The Firehouse Chronicles – Episode 11

This post is the next in a series of posts I have dubbed “The Firehouse Chronicles.” See all episodes. Since we are in destruction mode and have a dumpster blocking the driveway, we proceed to make short work of tackling the kitchen, pulling down the strange hutch in the middle of the island to open up the room. Jim works to tie up or decommission the snaking wiring. We are left with an odd island with two sinks in the middle of the room and overhead wiring hanging from the ceiling. Not pretty, but already the room is brighter and it again becomes easier to see the possibilities.The house is now coated in a thick layer of plaster dust, sawdust, and rogue nails prickling floors and walls.

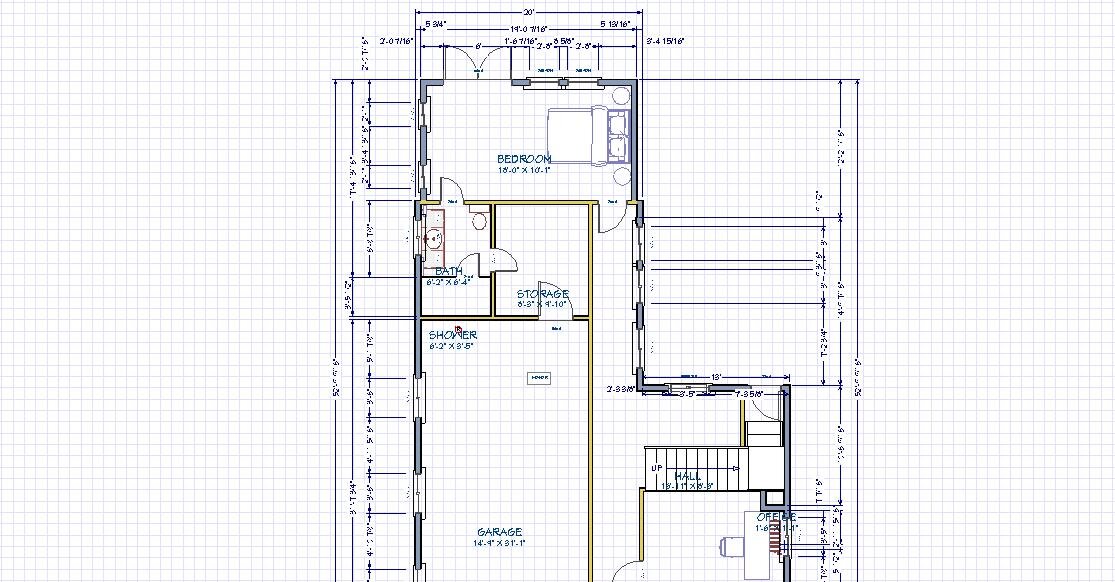

Now that we have things flayed open, we turn our attention back downstairs. Jim rents a cement cutter and slices trenches for the plumbing - toilet, vanity, shower drain. He digs around the base of the old iron sewer drain pipe that runs the height of the room to the ceiling and in one night, cuts the entire pipe out and hauls it out the back where it is added to a pile of metal scrap that I will eventually take to the recycling place and gleefully come home with $23 (it's the little things). The old iron pipe is replaced with black PVC pipe that will fit within a standard wall.Alongside the new sewer pipe is a beautiful old six-inch thick wooden beam. Like the sewer pipe, this beam also poses an impediment to a new wall due to its thickness and so we decide to replace it with a slimmer steel beam. We save the old beam, hoping to find a place to use it.We head to Pacific Supply Co., a warehouse filled with huge racks of steel beams, pipes, spikes and flat metal sheathing. The air inside is heavy with a tangy taste of iron and the smell of grease. The noise of a huge saw that cuts the steel to customer's specifications interrupts all conversation. The saw is run by a guy in greasy blue coveralls who speaks in grunts as he hoists a long length of steel onto a cart and wheels it noisily over to the machine. We have two 3-inch diameter lengths of steel cut into 15-foot pieces with the intent of welding them together to create the new beam.By the time we're ready to place the beam, however, the reality of another 10 hour day has Jim abandon the welding and opting for a single beam, which from an engineering point of view, is more than adequate. I use a circular saw equipped with a blade that cuts through steel to slice four vertical slits into the bottom of the beam, which Jim then uses pipes wrenches to flay outwards, creating a base for the beam that we nuzzle into a deep bed of concrete. Equipped with gloves, ear protection, a full plastic face protector, I have grown used to the flying sparks and squealing noises, but am still hyper vigilant about the placement of my various extremities.Jim sets up his GoPro camera and begins a VLOG of what will become 1-minute recordings of our progress. The first two encompass what I have described above (dramatic sparks and all):Once we get the steel beam in place, we engineer a complex array of wooden planks, ropes, and the trusty car jacks to wedge it into its new home, where it can settle into its job of holding up two-thirds of the house. Next, we fill in the trenches that hold both the new beam, the new sewer stack and all the new plumbing and slap the cement smooth.It's been another 12 hour day that ends with more doses of Advil. I am my own pain-relief commercial.The next day, Jim goes to work, so Chloe and I head over to clean up a little and I take some measurements so I can try to plan out the bathroom with real numbers and figure out what to do for a vanity, doors and determine how big the shower should be.This leads to hours researching a tool (my motto: there's always an app for that!) that I can use to plan the new bathroom leading me to find Home Designer which I buy for $99. It seems reasonable given that there will be lots of planning to do in the coming months. What I don't anticipate is the learning curve. I spend hours entering the correct measurements and eventually have all three floors of the house mapped out. When I go into 3-D mode however, the roof of the house looks like it was built by an oragami artist on crack. Jagged roof peaks and folds everywhere. Various floors appear to be made from grass and parts of the roof are open to sky. But eventually, I come up with a plan for the bathroom that looks almost legible. I even manage a 3D rendering. I am beginning to feel a little like Joanna Gaines (if you haven't already become addicted to "Fixer Upper" I don't recommend it, unless you have a ton of time on your hands, but I'll just say, it's available on Netflix). Olivia has already accused me and Jim of being "just like Chip and Joanna" and I have to laugh, especially as I create my first 3D rendering of the bathroom. I am weirdly flattered by the comparison to Chip and Joanna, as they appear to be a couple who enjoy each other's company. They're playful and silly, Chip lends a hand in the demos (Jim is quick to notice he is too clean for a guy doing demo) and Joanna creates plans (and 3D renderings). As Olivia put it, "Chip is a big kid, just like Jim, and you are like Joanna, the practical one." It's interesting to see how my child views my relationship with Jim, since she doesn't say much about it, and I am glad she sees the positive. If you promise not to laugh, I'll leave you with my first 3D rendering. Thanks Joanna Gaines!

Now that we have things flayed open, we turn our attention back downstairs. Jim rents a cement cutter and slices trenches for the plumbing - toilet, vanity, shower drain. He digs around the base of the old iron sewer drain pipe that runs the height of the room to the ceiling and in one night, cuts the entire pipe out and hauls it out the back where it is added to a pile of metal scrap that I will eventually take to the recycling place and gleefully come home with $23 (it's the little things). The old iron pipe is replaced with black PVC pipe that will fit within a standard wall.Alongside the new sewer pipe is a beautiful old six-inch thick wooden beam. Like the sewer pipe, this beam also poses an impediment to a new wall due to its thickness and so we decide to replace it with a slimmer steel beam. We save the old beam, hoping to find a place to use it.We head to Pacific Supply Co., a warehouse filled with huge racks of steel beams, pipes, spikes and flat metal sheathing. The air inside is heavy with a tangy taste of iron and the smell of grease. The noise of a huge saw that cuts the steel to customer's specifications interrupts all conversation. The saw is run by a guy in greasy blue coveralls who speaks in grunts as he hoists a long length of steel onto a cart and wheels it noisily over to the machine. We have two 3-inch diameter lengths of steel cut into 15-foot pieces with the intent of welding them together to create the new beam.By the time we're ready to place the beam, however, the reality of another 10 hour day has Jim abandon the welding and opting for a single beam, which from an engineering point of view, is more than adequate. I use a circular saw equipped with a blade that cuts through steel to slice four vertical slits into the bottom of the beam, which Jim then uses pipes wrenches to flay outwards, creating a base for the beam that we nuzzle into a deep bed of concrete. Equipped with gloves, ear protection, a full plastic face protector, I have grown used to the flying sparks and squealing noises, but am still hyper vigilant about the placement of my various extremities.Jim sets up his GoPro camera and begins a VLOG of what will become 1-minute recordings of our progress. The first two encompass what I have described above (dramatic sparks and all):Once we get the steel beam in place, we engineer a complex array of wooden planks, ropes, and the trusty car jacks to wedge it into its new home, where it can settle into its job of holding up two-thirds of the house. Next, we fill in the trenches that hold both the new beam, the new sewer stack and all the new plumbing and slap the cement smooth.It's been another 12 hour day that ends with more doses of Advil. I am my own pain-relief commercial.The next day, Jim goes to work, so Chloe and I head over to clean up a little and I take some measurements so I can try to plan out the bathroom with real numbers and figure out what to do for a vanity, doors and determine how big the shower should be.This leads to hours researching a tool (my motto: there's always an app for that!) that I can use to plan the new bathroom leading me to find Home Designer which I buy for $99. It seems reasonable given that there will be lots of planning to do in the coming months. What I don't anticipate is the learning curve. I spend hours entering the correct measurements and eventually have all three floors of the house mapped out. When I go into 3-D mode however, the roof of the house looks like it was built by an oragami artist on crack. Jagged roof peaks and folds everywhere. Various floors appear to be made from grass and parts of the roof are open to sky. But eventually, I come up with a plan for the bathroom that looks almost legible. I even manage a 3D rendering. I am beginning to feel a little like Joanna Gaines (if you haven't already become addicted to "Fixer Upper" I don't recommend it, unless you have a ton of time on your hands, but I'll just say, it's available on Netflix). Olivia has already accused me and Jim of being "just like Chip and Joanna" and I have to laugh, especially as I create my first 3D rendering of the bathroom. I am weirdly flattered by the comparison to Chip and Joanna, as they appear to be a couple who enjoy each other's company. They're playful and silly, Chip lends a hand in the demos (Jim is quick to notice he is too clean for a guy doing demo) and Joanna creates plans (and 3D renderings). As Olivia put it, "Chip is a big kid, just like Jim, and you are like Joanna, the practical one." It's interesting to see how my child views my relationship with Jim, since she doesn't say much about it, and I am glad she sees the positive. If you promise not to laugh, I'll leave you with my first 3D rendering. Thanks Joanna Gaines!